Low PSI processing (SWISSPACER, Multitec)

Equipped for modern low psi profiles

Modern technology for modern technology

One of our highlights: ultrasonic welding technology for the industrial processing of modern low psi profilesSwisspacer, Multitec, Precision) to spacer frames.

Leaflet Low Psi-Profiles_german

Leaflet Low Psi-Profiles_eng

With our tried-and-tested Roweldo-Romillo combination, one person can achieve cycle times of less than 30 seconds.

Suitable for processing all standard low psi profiles such as Swisspacer, Multitec, Precision or comparable products.

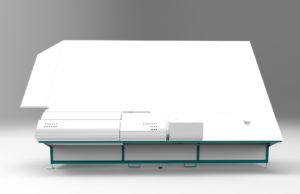

Roweldo XL - the 4-head welding system

- Individually inserted frame parts are automatically joined and welded

- Automatic welding of all four corners in one operation

- Clean corners, therfore a proper butyl surface and minimal thickening

- Interior view is identical to inserted corners without any deformities

- High frame and dimensional stability

- Automatic positioning of the welding head through online connectivity

- Cycle times of less than 30 seconds

Romillo XL - the cutting machine

- Frame parts are milled to 45°

- Automatic insertion of the corner brackets

- Longitudinal welding of the profiles for endless connection

- Compatible with 25-compartments magazine PWM 20 XL

- Cycle times of less than 30 seconds

- Minimal waste due to optimum residual length management

For smaller quantities we recommend the combination of Roweldo S and Bendit with Low Psi option.

Roweldo S - the 4-head welding system

- Automatic welding of the corners one after the other

- Manual positioning for the welding process

- Clean corners, therfore a proper butyl surface and minimal thickening

- Interior view is identical to inserted corners without any deformities

- High frame and dimensional stability

- Automatic positioning of the welding head through online connectivity

- Cycle times of less than 50 seconds

Bendit with Low Psi Option

- Integration of Multitec, Precision, Swisspacer processin

- Individual magazine configurations between 10 and 25 compartments

- Universal bending tools for almost all hybrid profiles

- Tight corner radii

- Rolling technique to support plastic deformation

- Counter support bending with profile-specific tools for almost any profile

- Modular machine design for perfect customisation

- Large one-piece frames

- Integrated radius bending

Subject to technical changes

© 2025, Rottler und Rüdiger und Partner GmbH. All rights reserved.